The Brief: design and manufacture a light with motion

Consultancy direction, presentation by Jemima Meil

Touchpoint

- Our consultancy is formed and have ideated the direction in which we wish to pursue

- The next steps are to branch off and form personal briefs, outlining our specific directions for the project

- The consultancy may be used throughout this project, to bounce ideas off eachother and simulate an industry setting

Personal Brief

Touchpoint

- I will look at physics phenomona as the driving force behind the light's function

- The form will be inspired by gorgeous italian design movements throught the ages

- Taking inspiration from the curiosity surrounding the Newton's cradle

Ideation

Touchpoint

- A few big ideation sessions left me with a vast range of tangible ideas. I used design books to excite my imagination and provoke ideas

- The final favourites (identified with green marks on pages), will be taken forwards to develop in 3D through sketch modelling

Continued ideas and Sketch Model Exploration

Touchpoint

- After long and hard deliberation, I have decided to go for an idea that revolves around the premise of square wheels and arbitrary timing of the day

- I am currently unsure where the light element will come into play, however I am inspred by the form and and see the potential in this design!

Development of the selected design

Touchpoint

-

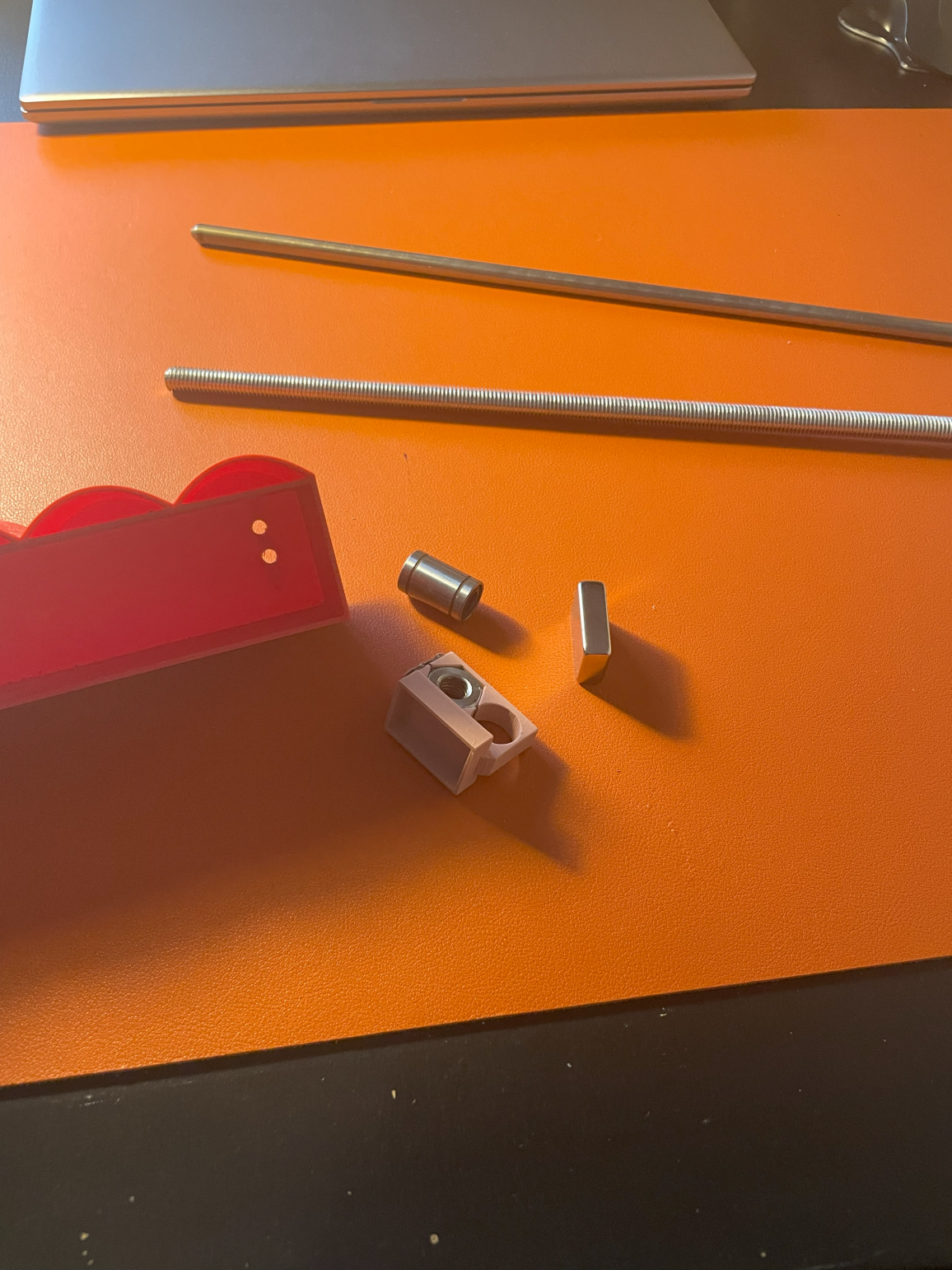

This has been a difficult yet exciting process of problem solving in order to get the design working

-

I am pleased with the pace at which I have worked, starting this process early meant I have not had to rush when countless unforseen errors have cropped up

-

From different drive mechanisms, different code variations, and different stepper motor setups- I have eventually arrived at a functional and reliable prototype!

Final detail design

Touchpoint

-

This final round of ideation was used to dive further into details of the design, a more complete product

-

This final round of ideation was very useful for collecting all ideas into one vision, allowing production of the first prototype to begin

The Final Result

Cascade was selected to be featured in the Product of South Bank final year degree show!

Here is a snippet of it in action!

Conclusions and Forecast

This brief has taught me an incredible amount! It has bettered my design process, improved my scketching skills, forced me to think outside the box and introduced me to electronics!

To improve on the project, I would spend more time on the deisgn details, to tweak the proportions of the design. I would also give the product a glossy paint job in a Memphis colourscheme. Additionally, I would use a rotary encoder so that the relative position of the cube is always known, making it more user friendly. Finally, I would make the light projections more crisp and precise, while also eliminating light bleed!